Insight

Types of Internal Packaging Materials

Internal packaging refers to the materials used to protect and contain products within their primary packaging. It’s essential for preventing damage during transportation and storage.

Here are some common types of internal packaging:

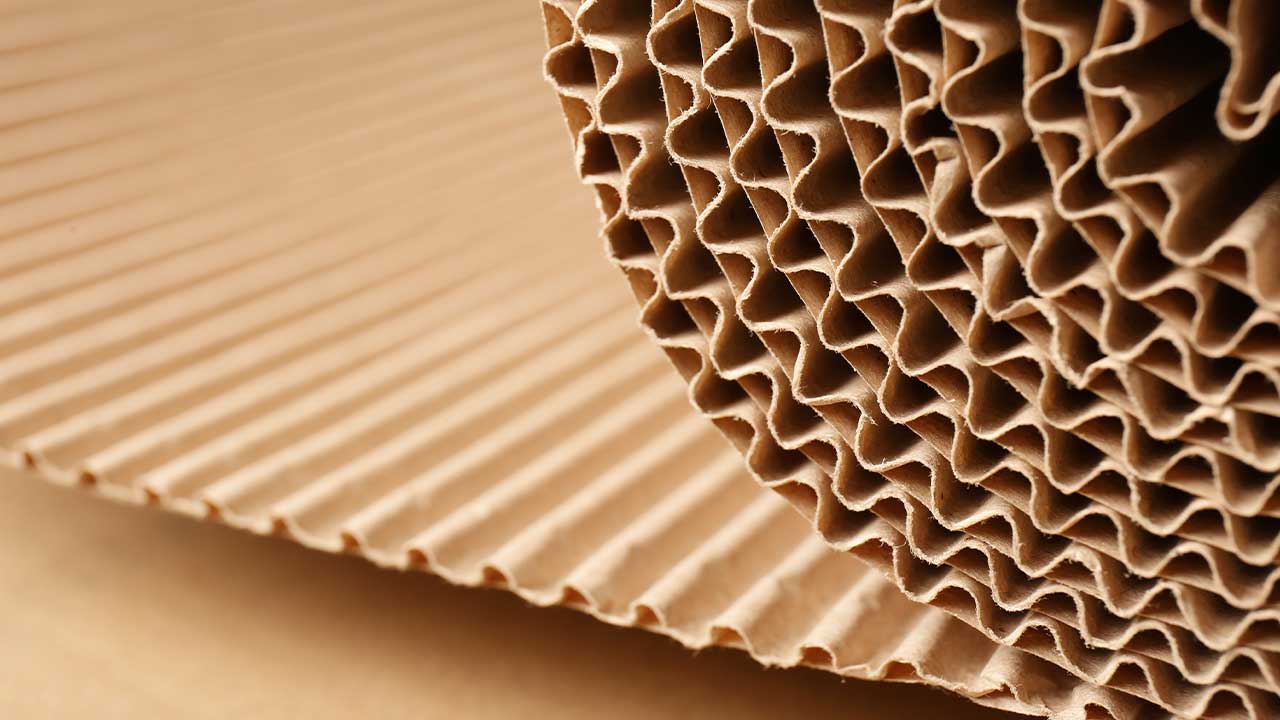

1. Cardboard Flute

Internal structure flute or channels provide resistance to avoid crushing and provides cushioning during handling and stowage.

Corrugated sided flute is mainly used as interior packaging to separate and protect individual products. It is extremely flexible and can be shaped around the product to protect them from damage. It should be self-attached to the product, leaving the flat side visible outside.

2. Plastic bubble

Plastic bubble is excellent for irregular forms due to its versatility.. It is very light, shock resistant, and recommended for very fragile products. Bubbles must be attached to the product, leaving the smooth side outside.

3. Poly Foam

It is very similar to plastic bubble with same characteristics but having less resistance to sharp objects.

4. Paper craft

Serves to cover irregular surfaces, or thinly cover an area to avoid tears, and to hide valuable things from being visible thus decreasing the possibility of theft. It is recommended to wrap products with higher value , only if they are upto medium size and have a good container – an example is laptops.

5. Paper filler

Paper filler is suitable for stuffing within boxes. Paper is pressed between products, thus immobilizing the products . It is one of the most ecological and economic fillings. It is useful against impact and crushing damages.

6. Honeycomb paper

Honeycomb paper is a lightweight yet strong material made from sheets of paper that are glued together in a hexagonal pattern, resembling a honeycomb. It absorbs shocks more efficiently, thus providing great protection.

7. Air cushion

Air cushion packaging is a dual material solution of a corrugated box and plastic film bag that is filled with air.

Benefit

- Eliminates product damage in transit

- Flexibility to pack different products in the same pack

- Minimises shipping costs and carbon emissions as it is lightweight

- Eliminates the need for additional fitments or loose fillings

- Environmental friendly – corrugated box is made from a renewable resource

- Easy to recycle – simply remove the film and send corrugated box for recycling